Ask for quotation

Ask for quotation

COOKIES and PERSONAL DATA - our web site may use some of cookies files. By using our website, you agree to let us use cookies, with accordance to your browser's settings. See also our pesonal data protection policy.

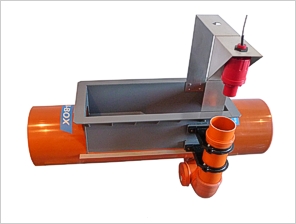

PALMER BOWLUS MEASURING FLUME

Flow rate measurement with Palmer-Bowlus ZPB flume and FLOWBOX flow meter

.......................

SUBJECT OF THE OFFER

The subject of our offer is a Palmer Bowlus flume intended for measuring momentary and total flow of the liquid in gravitational channels, with the use of an ultrasonic FLOWBOX flow meter. Upon request, it’s also possible to carry out pre-investment technical consulting, as well as subsequent installation, launching* and protocol-based delivery of flow meter for the use. We also sell individual elements of the measuring set manufactured by us (e.g. only Palmer-Bowlus flume or only flow meter FLOWBOX).

Download

Palmer-Bowlus flume data sheet

FLOWBOX flow meter data sheet

FLOWBOX flow meter manual

Declarations of conformity

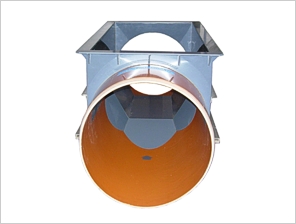

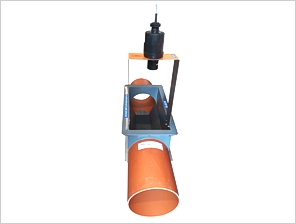

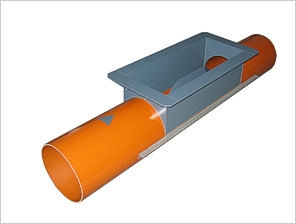

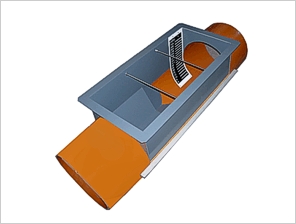

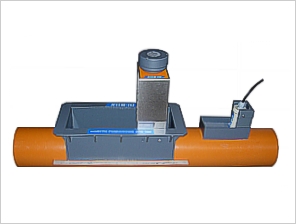

MEASURING SET DESIGN

- Palmer-Bowlus measuring flume

- FLOWBOX flow meter

ASSUMPTIONS

The liquid flow rate measurement with Palmer-Bowlus flume and water rise method in circular channels is based on the actual liquid level measured by the ultrasonic sensor (radar sensor, optional) at the hydraulic structure converted into the value of flow ratio by the measuring transmitter.

The basic condition to apply the method is to provide, undisturbed and laminar flow in a measuring flume and free outflow of liquid from the measuring flume.

Palmer - Bowlus flume, in accordance with ISO 4359 "Liquid flow measurement in open channels. Rectangular, trapezoidal and U-shaped flumes” is one of the metering flumes intended for flow measurement in ducts with gravity flow. It is recommended for circular channels with gravity flow and unpressurized lines. The flume provides a close relation between liquid level and flow rate in a duct or a pipeline.

FEATURES:

- Optimum measuring accuracy of the flow rate

- Standard flume dimensions

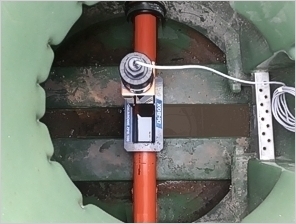

- Easy installation in circular channels or pipelines

- Easy flume installation

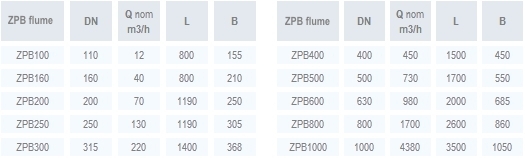

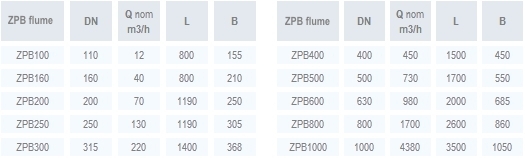

THE FAMILY OF PALMER-BOWLUS FLUMES

We also offer Palmer-Bowlus flumes in specialised versions dedicated to various applications.

Inter alia we recommend Palmer-Bowlus flumes:

- with SIDE MEASURING STACK for measurement of foamy liquid flow,

- with VERNIER for visual determination of current flow rate in the pipeline, without electronic measuring instruments,

- in HERMETIC version (antiodor),

- with additional measurement (dissolved oxygen, pH value, ORP, conductivity) of a liquid (with FLOWBOXplus flow meter).

PALMER-BOWLUS FLUME ASSEMBLY RECOMMENDATIONS

- Install the Palmer-Bowlus flume on the pipeline by means of inserting channel in pipeline goblet or typical hydraulic muff in the way of assuring the durability and tightness of the connection, remembering about the proper flume orientation (the indicator in the channel shows the flow direction).

- Install the Palmer-Bowlus flume in the horizontal position without drops.

- The Palmer-Bowlus flume must be properly connected to the pipeline (no gap, smooth transition).

- Perform support of the flume assuring its immobilization (in case of bigger flumes).

- Provide free, undisturbed inflow and outflow of liquid from the measuring flume by means of ensuring long enough straight inlet and outlet channel parts with propper slope.

- Provide free outflow of from the measuring Palmer-Bowlus ZPB flume.

- SPA 380-4 sensor should be installed in the durable and safe way in the given measuring handle. The handle screwed to the flume by means of 8 x M5 should guaranteed solid and safe placement of the sensor during work.

- Put the measuring sensor in the handle in accordance with the drawing. Use the washers. Screw the nut 2".

- Connect the ultrasonic sensor with the M1600 transmitter with a cable.

- It is recommended to use the roofing of the transmitter M1600 protecting it against direct influence of the atmospheric factors (for instance: rain, snow) or installation in safety case.

Exemplary Palmer-Bowlus flumes manufactured by DI-BOX------------

Ask for quotation

Ask for quotation